Unlocking the Advantages of Carbon Fiber Reinforced Nylon for Your Projects

- Bryan McFarland

- Oct 14, 2025

- 4 min read

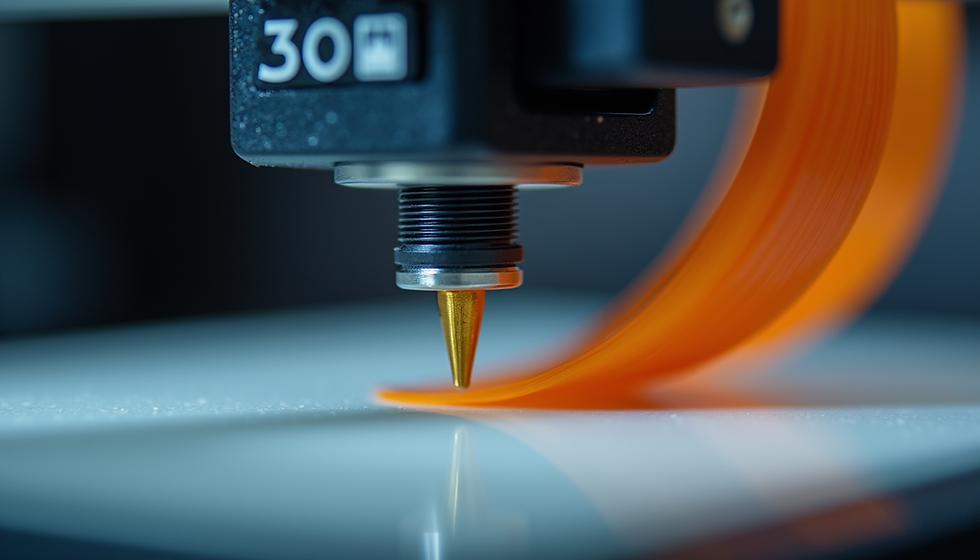

Carbon fiber reinforced nylon is gaining significant attention across myriad industries for its impressive attributes. This composite intertwines the lightweight benefits of nylon with the formidable strength of carbon fiber, making it a top choice for various applications. This blog post dives deep into the advantages of carbon fiber reinforced nylon and discusses how this material can enhance your projects remarkably.

What is Carbon Fiber Reinforced Nylon?

Carbon fiber reinforced nylon is a composite made from nylon, a synthetic polymer, mixed with carbon fibers. This combination results in a material that is not only lightweight but also remarkably strong and durable. For instance, carbon fiber reinforced nylon can exhibit up to 2-4 times the tensile strength of standard nylon.

During manufacturing, specific ratios of nylon and carbon fibers are blended together, followed by molding or extrusion to create desired shapes. The material can take various forms, including sheets, rods, and custom parts, making it exceptionally versatile.

Lightweight Yet Strong

One of the remarkable advantages of carbon fiber reinforced nylon is its lightweight nature. This composite is significantly lighter than traditional materials like metal, and can be approximately 30% lighter than regular nylon. In industries like aerospace, automotive, and sporting goods, this weight reduction can be crucial.

Despite being lightweight, carbon fiber reinforced nylon excels in strength. The addition of carbon fibers gives this composite outstanding tensile strength, typically around 100-150 MPa (megapascals), allowing it to resist deformation and breakage under stress. This impressive strength-to-weight ratio explains why engineers and designers are increasingly adopting this material.

Enhanced Durability

Durability is another standout feature of carbon fiber reinforced nylon. This material shows excellent resistance to wear, impact, and environmental factors such as moisture and chemicals. For example, in the automotive sector, components made from this composite can endure daily use while retaining their structural integrity, showing a lifespan increase of about 25% compared to parts made from standard materials.

In sporting goods, equipment such as high-end bicycles or tennis rackets made from carbon fiber reinforced nylon can withstand significant levels of stress without degradation, ensuring longevity and consistent performance.

Design Flexibility

One of the key benefits of carbon fiber reinforced nylon is its design flexibility. This material allows for complex geometries that would be tough to achieve with traditional materials. In custom parts, designers can create lightweight components that do not require additional support structures, leading to streamlined designs and reduced manufacturing costs.

For instance, a manufacturer creating a custom drone housing can design intricate shapes that provide both aerodynamics and strength without the need for bulkier supports, improving overall efficiency.

Cost-Effectiveness

While carbon fiber reinforced nylon may initially cost more than standard nylon or other materials, its long-term advantages can make it a cost-effective choice. The combination of durability and strength means reduced maintenance and replacement costs over the lifecycle of the product.

Additionally, its lightweight nature can contribute to cost savings in transportation and fuel. In the automotive industry, manufacturers have reported up to 15% savings in fuel costs due to weight reduction from using this composite material. Ultimately, even with the higher upfront cost, carbon fiber reinforced nylon can prove to be financially advantageous in the long term.

Applications Across Industries

The versatility of carbon fiber reinforced nylon leads to a broad range of applications in various sectors. Here are some notable examples:

Aerospace: Used in aircraft components where weight reduction is essential, significantly boosting fuel efficiency.

Automotive: Incorporated in components like brackets and structural parts, optimizing performance and minimizing weight.

Sporting Goods: Found in high-performance equipment such as bicycles and fishing rods, where lightness and strength are vital.

Consumer Products: Utilized in durable items like phone cases and outdoor gear, offering a modern look and high resilience.

Environmental Considerations

As sustainability becomes more critical in manufacturing, carbon fiber reinforced nylon presents an eco-friendly option. This material can be made with recycled nylon, helping to minimize waste and reduce the environmental impact linked to traditional manufacturing processes.

Moreover, because of its lightweight properties, products made from carbon fiber reinforced nylon require less energy during transportation. This aligns with the increasing demand for sustainable materials across industries and continues to gain traction as a solution for environmentally-conscious manufacturing.

Final Thoughts

Carbon fiber reinforced nylon is a remarkable material that seamlessly combines lightweight features with tremendous strength, durability, and design flexibility. Its applications are widespread across multiple industries, providing a strategic advantage for engineers and designers aiming to enhance their projects.

As the spotlight on high-performance materials broadens, carbon fiber reinforced nylon emerges as a leading solution that aligns with modern manufacturing needs and environmental considerations. By leveraging the benefits of this composite material, you can elevate your projects, ensuring they are not only efficient but also sustainable.

Integrating carbon fiber reinforced nylon into your designs could be the key to achieving the performance and durability you seek. Whether you're working in aerospace, automotive, or consumer products, this material can provide the competitive edge necessary for success.

Comments